Shomoukh Al Az Company, one of 16 companies under Hajar Group, was established to play a major roll in Iraq’s manufacturing industry for construction material.

With the enormous reconstruction efforts of the current government, the huge government budget and the relative stability in the country, in sight, we have decided to invest in one of the main raw material manufacturing in the electricity and telecommunication industry: Copper Rods.

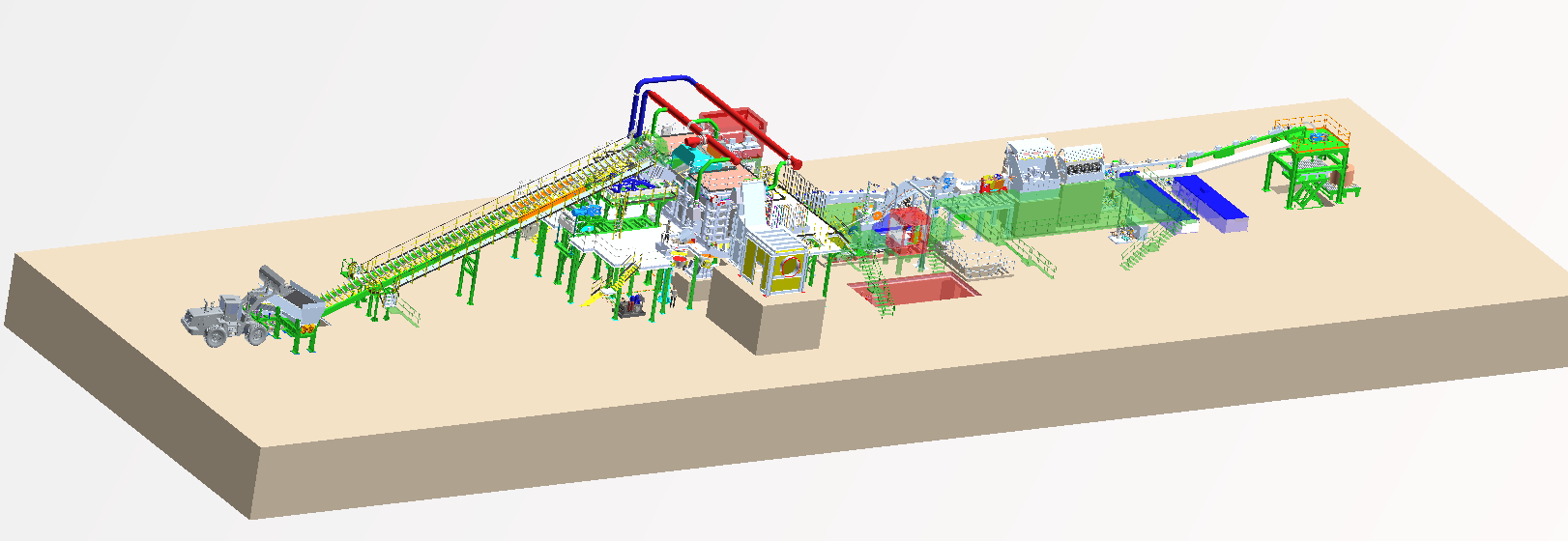

Smoukh Al Az’s first major project and achievement is a PPP – Public Private Partnership Agreement with the Iraqi Central Government for the construction and operation of a new Copper Recycling plant in Fallujah, near Baghdad, to process copper scrap, mainly blister and high copper content scrap, into annually approximately 30.000 metric tons of FRHC Copper rod.

Recycling of copper scrap is one of the best examples of a circular economy. Melting, refining and casting the desired final product allows great energy savings and avoids additional spoiling of mines. Copper products produced from mines requires 2.5 times the energy used when starting from scrap and creates 750 times (!) the SO2 Pollution.

With our state of the art Recycling Plant we can use and melt all kinds of copper scrap up from bright copper from the drawing shop (near to cathode purity) to old scrap with a minimum copper content around 93%.

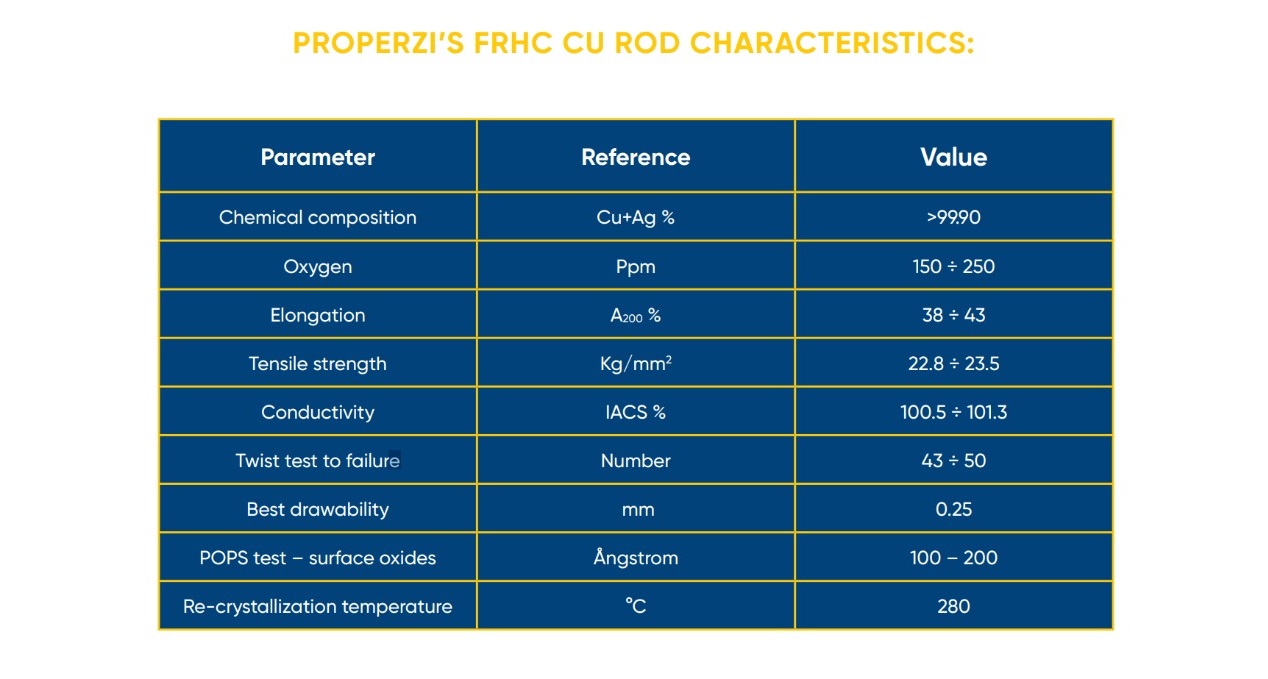

The Copper Recycling Plant is build on a plot of land measuring 50.000m2, with a 14.000m2 closed area for the main machines for the plant, and is within an industrial area in Fallujah. The approximately 100MT daily output will be of 8mm copper rod of minimum 99,92% purity, complying with Standard EN 1977:1998 CW005A class material, also defined in ASTM B-49.

There is enough space and allocated infrastructure to add a LV and MV cable plant as a second development stage with a accumulated output for LV and MV cables of 20.000MT per annum.

The Continuus-Properzi Company (Italy) is providing the main equipment and Engineering Services, owning the exclusive Properzi Copper Fire Refining Technology.

The Reverberatory Furnace technology is designed and capable to process copper scrap into liquid metal with a controlled content of impurities. The production of this molten copper is suitable to produce FRHC (Fire Refined High Conductivity) copper rod, strip, billets or copper ingot.

As a major difference to other furnaces, the charging door is now located on the roof of the Furnace thereby allowing a faster, simpler, and more automatic operation. The loading system is accomplished via an industrial belt conveyor.

The Reverberatory Furnace can be fed with 100% copper scrap with minimum 93% Cu that is a mix of many different kinds of copper scrap thereby saving hundreds of dollars per ton on the raw material!

The “Prime Rod” Copper CCR Line, also provided by Continuous Properzi, is an automatic wheel and belt type, which converts the molten metal into a continuous solid cast bar.